There’s a spike of interest in 3D printing from various industries, but what does it offer designers and architects? We chat with the Singapore branch of 3D Printing Studios – one of our amazing #SGID17 partners!

October 13th, 2017

When 3D Printing Studios opened its first space in Sydney in 2013, it was – incredibly – just the fifth one-stop 3D-printing venture of its kind in the world. That’s how recently the technology has entered the mainstream, despite the fact that it has existed for years.

Now you can find the company in several Australian cities, in Malaysia, and here in Singapore. The architecture and interior industries make up a significant proportion of its business along with the medical tech, engineering and automotive industries. And of course, there will always be a stream of consumers doing their own personal product development, and disrupting traditional product manufacturing and procurement processes as they do.

So when we asked 3D Printing Studios to be involved in Singapore Indesign 2017 (#SGID17) as the printer for our #SGID Futures Debate trophy (which was all about disruption!), it was an easy fit.

“Communication is key – especially at the beginning of a project,” he adds. Among their most popular services is translating 2D sketches (and even photographs of existing buildings) to 3D models, but they are also called on to assist later in the design process.

Interior layout models are proving to be popular communication tools for interior designers and developers, explains Joo. And marketing models (often in colour) of entire projects are becoming a crucial sales tool for developers. In the Australian state of New South Wales, developer approval models are necessary by law for submissions to councils, and Joo believes that it will only be a matter of time before this becomes mandatory in Singapore too.

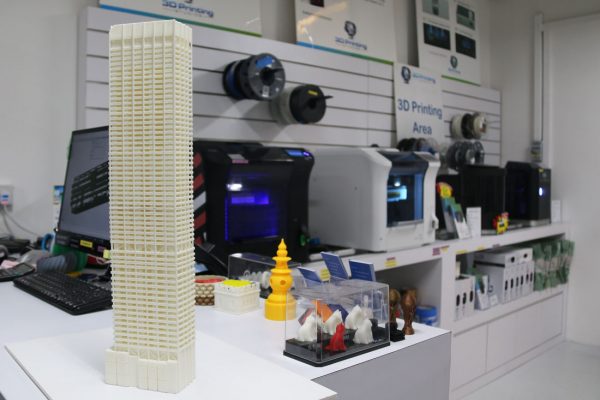

Other common requests are land-use models and terrain models, the latter often being requested by mining and palm oil companies. Drones are typically used to scan a piece of land, and the data is translated into 3D form by 3D Printing Studios before being printed, with colour transferred into the printing medium if requested. We saw a variety of 3D-printed models in Joo’s studio, as you can see above and below.

A large model pieced together from individually printed parts at 3D Printing Studios Asia’s Singapore studio.

But Jason makes a solid case for the benefits of 3D printing for architects and designers: speed (with a turnaround time of one week for architectural models from ready 3D drawing files), accuracy and detail (since the printed form is a direct translation from a CAD file), and cost. And other technologies, such as AR and VR, require far more substantial investments of time and money.

It is becoming more common to see 3D printers embedded within architecture studios. Some of those I’ve spotted in Singaporean studios may well have been sold by 3D Printing Studios. Jason emphasises, however, that there’s still a lot of work to be done on increasing understanding and awareness of the steps that go into making a drawing file 3D-print ready. Training is part of the company’s offering.

A 3D printer in your own studio is not much use unless you have someone on staff who knows how to properly prepare the files. And doing that takes time. “People tend to think 3D printing is instant. They want to see the output immediately. It is fast, but there’s also work that goes into the pre-printing process that people need to have a better understanding of,” says Joo.

Jason Joo (Managing Director) and Paulene Siew (Operation Director and 3D Designer), 3D Printing Studios Asia.

The material options for 3D printing are increasing, and criticisms of the use of plastic are being met by options such as a biodegradable material with a corn-starch basis. This material, says Joo, is a popular choice for schools, but the less durable nature of the material means its use should be restricted to the indoors.

Metals – steel, titanium and even gold – are also being used for 3D printing, which could create serious disruption to the jewellery industry. And Joo explains how bio printing is already underway within some of the world’s major cosmetics companies, who create their own tissues for the testing of perfumes and skin products.

It’s a brave new world. Are you ready?

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

Channelling the enchanting ambience of the Caffè Greco in Rome, Budapest’s historic Gerbeaud, and Grossi Florentino in Melbourne, Ross Didier’s new collection evokes the designer’s affinity for café experience, while delivering refined seating for contemporary hospitality interiors.

Savage Design’s approach to understanding the relationship between design concepts and user experience, particularly with metalwork, transcends traditional boundaries, blending timeless craftsmanship with digital innovation to create enduring elegance in objects, furnishings, and door furniture.

Suitable for applications ranging from schools and retail outlets to computer rooms and X-ray suites, Palettone comes in two varieties and a choice of more than fifty colours.

Simon Liley, Principal Sustainability Consultant at Cundall, writes about how cyberpunk dystopias haven’t (quite) come to pass yet – and how designers can avoid them.

Beau Fulwood and Alison Peach on returning to a low-tech, first-principles concept of design as a strategy to combat climate change.

The internet never sleeps! Here's the stuff you might have missed

Overcoming pandemic hurdles to redefine guest experiences amidst Sydney’s bustling entertainment precinct, The Darling has undergone a two-year restoration that melds Art Deco interiors with the necessities of hotel living.

Welcome to the year of the Design Effect. This year’s theme aims to showcase the profound ripple effects that exceptional design can have on people, place and planet. Join in shaping this narrative by contributing your perspective before May 3, 2024, and become a part of the Design Effect movement.