Dr. Sascha Peters talks about the advantages and breakthroughs of additive manufacturing and how this technology is about to change many production processes forever. Olha Romaniuk writes.

March 23rd, 2016

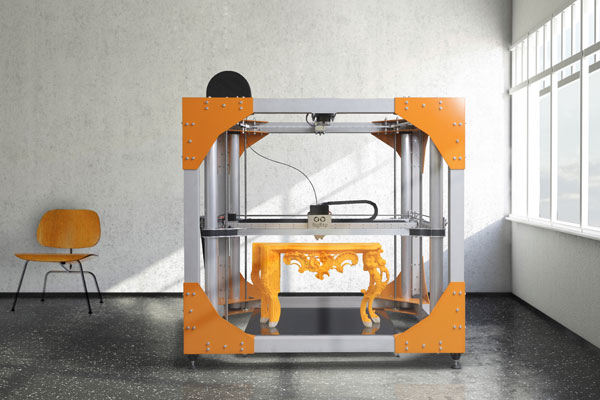

Top image: BIG Rep GmbH, Berlin

The founder of Haute Innovation, Dr. Sascha Peters, likens additive manufacturing or 3D printing to the Internet at its infancy. During the third edition of furniPRO Asia, held in conjunction with the International Furniture Fair Singapore, Peters spoke about the technology’s yet-untapped possibilities in many diverse industries, from the automotive, to the biomedical, design and construction sectors. He also presented a convincing look into the future of additive manufacturing, with examples of the latest projects and the biggest players pushing the limits of additive manufacturing technology today.

Opening his seminar with a question on whether additive manufacturing is a technology that is just a trend or one that is heading for the mass market, Peters called additive manufacturing the production technology of the next century. With many recent applications in different industries, Peters pointed out the potential to partially replace conventional production techniques such as milling or turning and develop new value creation opportunities.

“Additive manufacturing processes offer options that classical processes only provide to a limited extent,” explained Peters. “It is now possible to produce individual and complex geometries without an expensive moulding tool in similar mechanical properties compared to dye casting. That makes additive manufacturing technologies so interesting for medicine (e.g. dental implants), aircraft (e.g. brackets) and the automotive industries.”

In the creative sector, additive manufacturing is groundbreaking in that it means unprecedented savings of cost, time and materials, enabling a fabrication of complex geometries that are optimised for strength and weight. With examples of 3D printed houses being fabricated and assembled in only 20 hours (WinSun, China) with 80 per cent less labour, additive manufacturing lifts the previous impossibilities of implementation due to technical or financial restrictions in the construction sector.

Endless Flow by Dirk vander Kooij

“Additive manufacturing even permits products and concepts with complex geometries, hollow spaces, undercuts and movable components to be created,” said Peters. “The availability of construction kits and information about the design and operation, along with the software and component data, has resulted in a flood of developments by designers and architects.”

Mycelium Chair by Eric Klarenbeek

While predicting a more widespread implementation of additive manufacturing in the various industries, Sascha Peters does not see it completely taking over the traditional manufacturing principles and craftsmanship. Instead, he sees hybrid systems as the future of 3D printing, with additive principles combining with conventional technologies to bring out the advantages of traditional and additive manufacturing. Peters sites cases like the glass printing project at the MIT in Boston, where 3D printing is combined with glass moulding, and 3D printed yarn fabric project by the Royal College of Art student, where traditional sewing concepts are combined with custom machine control software to create impact resisting materials using cotton yarn and liquefied silicon.

Glacier Stool by NowLab Berlin

With additive manufacturing technologies continuously improving and evolving, Peters sees a great value and even greater range of applications of additive technologies across many disciplines. With heavyweight companies like Adidas, ARUP and GE Aviation taking note and implementing additive manufacturing in their latest projects, the global demand for the technology shows no signs of slowing down.

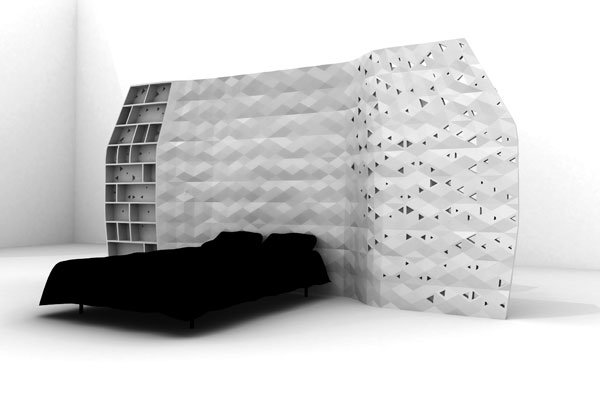

L`habitat imprimé by Francois Brument

“The overall market for additive manufacturing has grown by an average of 24.1 per cent in the last 25 years,” notes Peters on the growing demand. “Additive manufacturing has developed into a promising technology in the industrial context and it is being actively used more and more in production in a variety of different industries.”

A searchable and comprehensive guide for specifying leading products and their suppliers

Keep up to date with the latest and greatest from our industry BFF's!

Marylou Cafaro’s first trendjournal sparked a powerful, decades-long movement in joinery designs and finishes which eventually saw Australian design develop its independence and characteristic style. Now, polytec offers all-new insights into the future of Australian design.

Suitable for applications ranging from schools and retail outlets to computer rooms and X-ray suites, Palettone comes in two varieties and a choice of more than fifty colours.

Channelling the enchanting ambience of the Caffè Greco in Rome, Budapest’s historic Gerbeaud, and Grossi Florentino in Melbourne, Ross Didier’s new collection evokes the designer’s affinity for café experience, while delivering refined seating for contemporary hospitality interiors.

Singaporean studio Produce was recognised with the Best of the Best accolade at the INDE.Awards 2019, partnered with Zenith. We unpack the innovative and progressive spirit that earned them this ultimate regional honour.

What would a home on Mars look like? There’s no need to speculate as HASSELL’s proposal for NASA’s 3D Printing Centennial Challenge creates a hyperrealistic vision.

The internet never sleeps! Here's the stuff you might have missed

Overcoming pandemic hurdles to redefine guest experiences amidst Sydney’s bustling entertainment precinct, The Darling has undergone a two-year restoration that melds Art Deco interiors with the necessities of hotel living.

Leading the field in terms of ergonomics, this high-end office furniture from Buro is also designed with the evolving needs of the modern workplace in mind.

Landing in the city’s financial district for the first time, The Sebel Sydney Martin Place has had its modern interiors completed by Stack Studio.

Welcome to the year of the Design Effect. This year’s theme aims to showcase the profound ripple effects that exceptional design can have on people, place and planet. Join in shaping this narrative by contributing your perspective before May 3, 2024, and become a part of the Design Effect movement.